Factory making Industrial Dehumidifier Machinery System - ZCB SERIES Combined Desiccant Dehumidifiers – Dry Air Detail:

ZCB SERIES Combined Desiccant Dehumidifiers Widely used in glass, pharmaceutical, chemical, food, rubber, and fertilizer manufacturing; any process/material affected by moisture.

ZCB series Combined Desiccant Dehumidifiers incorporate many advanced features including an innovative double wall construction structure with superior air tightness and good insulation performance. Surface options of panels including galvanized steel, aluminum alloy, stainless steel or any combination permit an effective choice for all kinds of operational environments.

ZCB series Combined Desiccant Dehumidifiers are especially suitable for manufacturing process with humidity requirement from 10% to 40% at normal temperature.

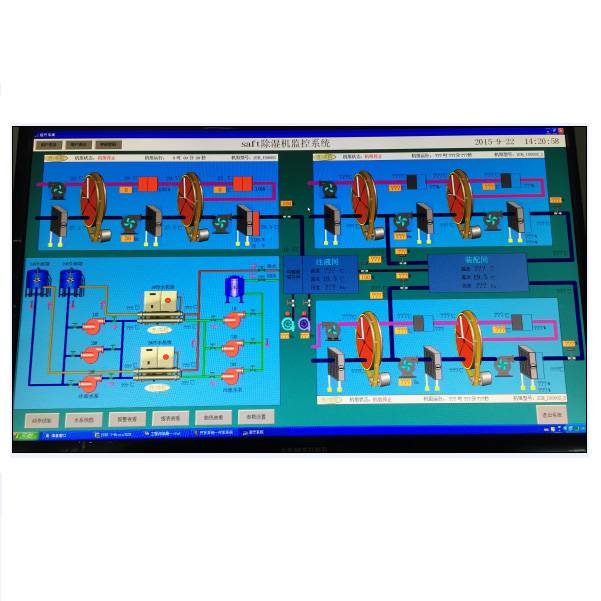

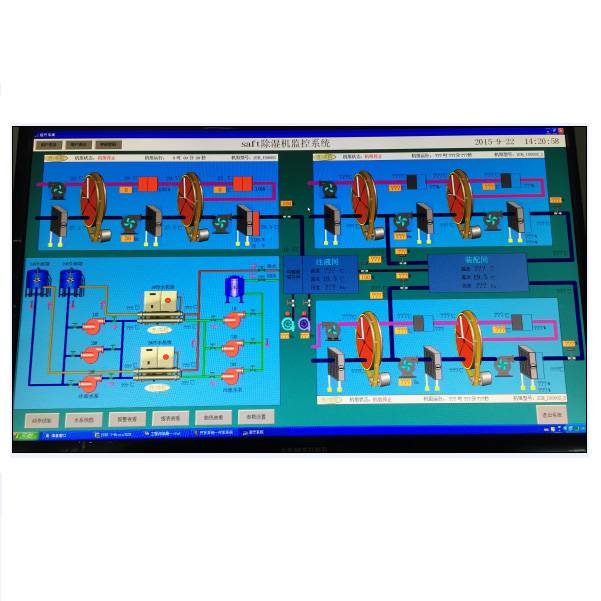

ZCB series Combined Desiccant Dehumidifiers can be customized to meet almost any requirements.Standard options of this series units include desiccant wheel, process fan,reactivation fan, reactivation heater, reactivation filter, pre-cooler, blend-cooler, post-cooler, heating coil for winter, G4 pre-filter ,medium filter and optional HEPA(high efficiency particulate air),air cooled or water cooled condensing unit ,chilled water piping, air duct system,PLC control system which can provide full temperature and humidity controls.

Features:

Heat recovery and energy saving technology

Silica gel desiccant rotor with high dehumidifying efficiency

Reactivation heating mode: steam or electrical

Anti cold bridge cabinet

Modular assembly, easy for installation

Main components:

desiccant wheel, reactivation fan, reactivation heater, reactivation filter, pre-cooler, medium-cooler, rear-cooler, heating coil for winter, pre-filter ,medium filter and HEPA(high efficiency particulate air) and cabinet.

|

ZCB Series Combined Desiccant Dehumidifiers |

||||||||||||||

| Technical parameters | ||||||||||||||

|

Model&Parameters |

ZCB-D/Z- 2000 |

ZCB-D/Z- 3000 |

ZCB-D/Z- 4000 |

ZCB-D/Z- 5000 |

ZCB-D/Z- 6000 |

ZCB-D/Z- 8000 |

ZCB-D/Z- 10000 |

ZCB-D/Z- 12000 |

ZCB-D/Z-15000 |

ZCB-D/Z-20000 |

ZCB-D/Z-25000 |

|||

|

Process air volume |

m3/h |

2000 |

3000 |

4000 |

5000 |

6000 |

8000 |

10000 |

12000 |

15000 |

20000 |

25000 |

||

|

External Static Pressure |

Pa |

≥300 |

||||||||||||

|

Regeneration air volume |

m3/h |

667 |

1000 |

1330 |

1670 |

2000 |

2670 |

3330 |

4000 |

5000 |

6670 |

8350 |

||

|

Regeneration power |

steam |

㎏/h |

40 |

60 |

80 |

120 |

150 |

200 |

250 |

300 |

400 |

500 |

600 |

|

|

diameter |

DN20 |

DN20 |

DN25 |

DN25 |

DN25 |

DN25 |

DN25 |

DN25 |

DN25 |

DN32 |

DN32 |

|||

|

Electrical |

kW |

20 |

30 |

40 |

50 |

60 |

80 |

100 |

120 |

150 |

200 |

250 |

||

|

Cooling water |

°C |

≤7 |

||||||||||||

|

Quantity |

t/h |

5 |

10 |

12 |

15 |

20 |

25 |

30 |

35 |

45 |

60 |

75 |

||

|

diameter |

DN40 |

DN40 |

DN40 |

DN50 |

DN50 |

DN50 |

DN65 |

DN65 |

DN65 |

DN80 |

DN80 |

|||

|

Rated power |

Steam |

kw |

3.05 |

4.2 |

5.2 |

7.1 |

7.1 |

9.8 |

13.3 |

14.2 |

20.7 |

24.2 |

29.7 |

|

|

Electrical |

kw |

23.05 |

34.2 |

45.2 |

57.1 |

67.1 |

89.8 |

113.3 |

134.2 |

170.7 |

224.2 |

279.7 |

||

|

Unit Weight |

㎏ |

1150 |

1450 |

1600 |

1800 |

2000 |

2200 |

2400 |

2700 |

2700 |

3000 |

3300 |

||

|

ZCB Series Combined Desiccant Dehumidifier Part Diemensions |

||||||||||||||

|

Model&Parameters |

ZCB-D/Z- 2000 |

ZCB-D/Z- 3000 |

ZCB-D/Z- 4000 |

ZCB-D/Z- 5000 |

ZCB-D/Z- 6000 |

ZCB-D/Z- 8000 |

ZCB-D/Z- 10000 |

ZCB-D/Z- 12000 |

ZCB-D/Z-15000 |

ZCB-D/Z-20000 |

ZCB-D/Z-25000 |

|||

|

Section Diemensions |

UxP |

800×700 |

900×800 |

1000×850 |

1100×900 |

1200×1000 |

1300×1050 |

1400×1150 |

1500×1300 |

1700×1450 |

1900×1650 |

2100×1750 |

||

|

Inlet air filter section |

A |

450 |

450 |

450 |

450 |

450 |

450 |

450 |

450 |

450 |

450 |

450 |

||

|

Pre-cooling section |

B |

750 |

750 |

750 |

900 |

900 |

900 |

900 |

900 |

900 |

900 |

900 |

||

|

Rotor section |

section size |

UxS |

800×1150 |

900×1300 |

1000×1400 |

1100×1500 |

1200×1600 |

1300×1700 |

1400×1850 |

1500×2000 |

1700×2200 |

1900×2400 |

2100×2600 |

|

|

C |

1050 |

1050 |

1050 |

1200 |

1200 |

1200 |

1200 |

1200 |

1350 |

1350 |

1500 |

|||

|

After cooling section |

D |

600 |

600 |

600 |

750 |

750 |

750 |

750 |

750 |

750 |

750 |

750 |

||

|

Supply fan section |

E |

900 |

900 |

900 |

1050 |

1050 |

1050 |

1050 |

1200 |

1200 |

1200 |

1350 |

||

|

Average air section |

F |

450 |

450 |

450 |

450 |

450 |

600 |

600 |

600 |

600 |

600 |

600 |

||

|

Mid-filter section |

G |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

600 |

||

|

Total length |

J |

5100 |

5100 |

5100 |

5700 |

5700 |

5850 |

5850 |

6000 |

6150 |

6150 |

6450 |

||

|

Fresh air section |

㎜ |

250×200 |

320×250 |

400×250 |

500×250 |

500×320 |

630×320 |

800×320 |

800×400 |

1000×400 |

1000×500 |

1250×500 |

||

|

Return air section |

㎜ |

250×200 |

320×250 |

400×250 |

500×250 |

500×320 |

630×320 |

800×320 |

800×400 |

1000×400 |

1000×500 |

1250×500 |

||

|

Process outlet air section |

㎜ |

400×250 |

500×320 |

630×320 |

800×320 |

800×400 |

800×500 |

1000×500 |

1000×630 |

1250×630 |

1250×800 |

1600×800 |

||

|

Regeneration air inlet section |

㎜ |

400×300 |

550×350 |

550×400 |

550×450 |

650×450 |

750×500 |

750×550 |

800×500 |

700×550 |

850×550 |

850×650 |

||

|

Regeneration air outlet section |

㎜ |

160×125 |

208×162 |

208×162 |

233×183 |

233×183 |

260×228 |

262×204 |

262204 |

302×234 |

332×257 |

487×340 |

||

Hangzhou DryAir Advantages:

1. Supplier for Military Projects in China

Qualified supplier for providing dehumidifying equipment for National Projects such as Satellite Launching base,Submarine compartment,Aircraft cabin,Minesweeper Sonar Storehouse,Positive and negative ions collider, Nuclear Power Station,missile base.

2.The founder of rotor Dehumidification in China.

We initiatively provide turn key Dry Room for Lithium Industries in China and has been devoted to Turn key solution which include research, design,manufacturing,installation, start-up, after-service of dehumidifying products since 1972.

3.Strong technical force

The unique company which have the certificate of GJB national army systems and ISO9001 systems among all the dehumidifier company of China.

The unique company which have research and development department and get the national research grants in all the dehumidifier company of China.

The national hi-tech enterprise.

The national innovation foundation .

4.Facility,Processing Machines and Testing Room

R&D center

Manufacturing Center

5.Largest Market Share in Domestic dehumidifying market

With advanced technology, perfect processing, good management, Dryair’s business develops very fast in lithium battery industry in recently years, we provide more than 300 sets low dew point dehumidifiers for lithium battery industry every year and is predominant in domestic dehumidifier market and our sales value is far ahead of other competitors

Product detail pictures:

Related Product Guide:

Eva Dry EDV 1100 Electric Petite Dehumidifier Product Overview

Thermally Activated Technology in Dehumidifiers

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for Factory making Industrial Dehumidifier Machinery System - ZCB SERIES Combined Desiccant Dehumidifiers – Dry Air, The product will supply to all over the world, such as: Gambia, Naples, Mauritius, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

We have been looking for a professional and responsible supplier, and now we find it.

-

ODM Manufacturer Standard Industrial Dehumidifi...

-

2018 Latest Design Compressorless Dehumidifier ...

-

Professional Design Dehumidifier With Casters -...

-

Europe style for Dehumidifier For Sale - ZCH-S...

-

Top Quality Desicant Rotor Dehumidifier - ZCLY...

-

China Gold Supplier for 8l Desiccant Dehumidifi...