Wholesale OEM/ODM Drying Dehumidifier - ZJRH SERIES NMP Recovery System – Dry Air Detail:

This system is designed to recycle NMP from the lithium-ion secondary battery electrodes manufacturing process. The hot solvent laden air from the ovens is drawn into DRYAIR’s NMP Recovery System where the NMP is recovered by a combination of condensation and adsorption.The cleaned solvent laden air is available for return to the process or discharge to atmosphere as per customer requirement.NMP stands for N-Methyl-2-Pyrrolidone,it is an expensive solvent In addition, the recovery and recycling of NMP can reduce running costs for lithium battery factories as well as avoiding air pollution.

Features :

97% recovery rate

NMP discharge: 12ppm

Conentration of recovered NMP Solvent:85%

Functional section:

Heat Ex-changer,Cooler

VOC concentrator,Process fan

Solvent Storage tank(optional)

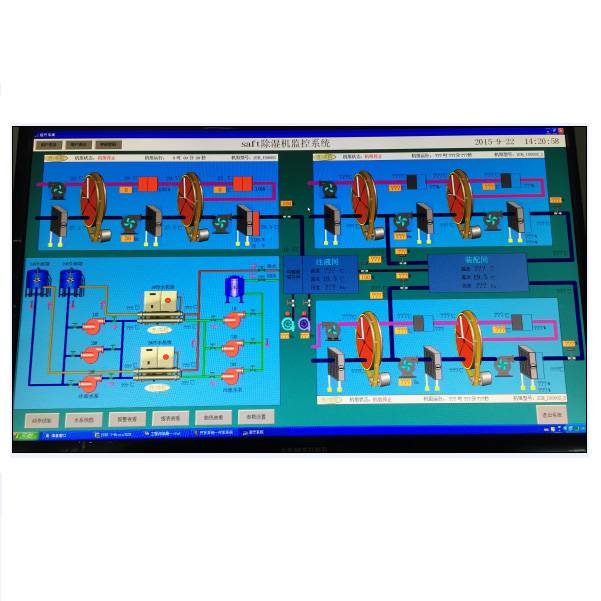

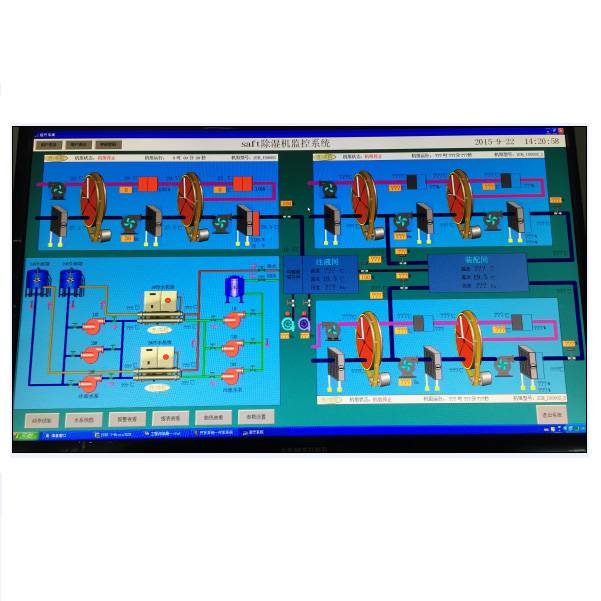

Siemens PLC

|

ZJRH Series NMP Recovery System |

||||||

|

Item |

ZJRH-D30-9000 |

ZJRH-D50-15000 |

ZJRH-D60-20000 |

ZJRH-D75-25000 |

ZJRH-D90-30000 |

ZJRH-D120-40000 |

|

Process air volume CMH |

9000 |

15000 |

20000 |

25000 |

30000 |

40000 |

|

NMP concentration in Discharged exhaust air |

≤50mg/m³ |

|||||

|

Concentration of Recovered NMP solvent |

≥85% |

|||||

|

NMP recovery rate |

≥97% |

|||||

|

Heat exchanger |

efficiency≥65% |

|||||

|

Cooler#1 kw(≤32℃ chilling water) |

38 |

63 |

84 |

105 |

126 |

168 |

|

Cooler#2 kw(≤10℃ chilled water) |

33 |

55.8 |

74 |

93 |

116 |

149 |

|

Process fan #1 KW |

5.5 |

11 |

15 |

15 |

18.5 |

22 |

|

Process fan #2 KW |

3 |

5.5 |

7.5 |

7.5 |

11 |

15 |

|

Reactivation fan motor KW |

2.2 |

2.2 |

3 |

3 |

4 |

4 |

|

Reactivation heate power KW |

12 |

18 |

22.5 |

27 |

36 |

48 |

|

Rated power KW |

22.7 |

36.7 |

48 |

52.5 |

69.5 |

89 |

Product detail pictures:

Related Product Guide:

working principle of dehumidifier

Thermally Activated Technology in Dehumidifiers

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for Wholesale OEM/ODM Drying Dehumidifier - ZJRH SERIES NMP Recovery System – Dry Air, The product will supply to all over the world, such as: luzern, Orlando, Bangladesh, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

China OEM Commercial Industrial Dehumidifier -...

-

Discountable price Industry Dehumidification Sy...

-

Factory source Dehumidifier For Car - REFRIGER...

-

Hot-selling Liquid Desiccant Dehumidifier - RE...

-

Low MOQ for Desiccant Rotor Dehumidification Sy...

-

Quoted price for Intelligent Compact Dehumidifi...